A gauge is a precision measurement tool widely used in industrial production to verify product dimensions (e.g., apertures, spatial geometries, etc.). It enables efficient quality control and process optimization, particularly in mass production of standardized components such as automotive parts. Compared to professional measuring instruments (e.g., micrometers or CMMs), gauges offer rapid, cost-effective inspections by providing pass/fail assessments. Common types include plug gauges (for hole diameters), thread gauges (for threaded features), and OD gauges (for external dimensions).

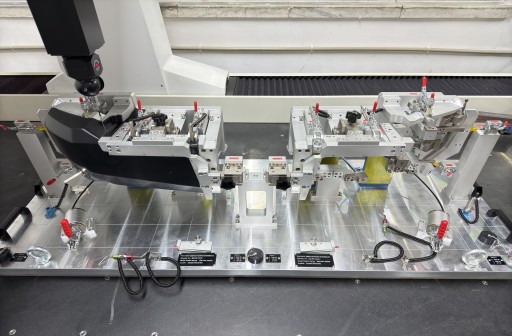

While gauges focus on specific dimensional tolerances, checking fixtures are modular systems designed to validate the overall conformity of complex parts, especially in assemblies. A checking fixture typically incorporates multiple gauging elements, locators, and clamps to simulate mating conditions—for example, ensuring a car door panel aligns correctly with its frame. Unlike standalone gauges, fixtures evaluate geometric relationships (e.g., flushness, gap consistency) and are critical for First Article Inspections (FAI) in industries like aerospace and automotive. Both tools complement each other: gauges ensure precision at the feature level, while fixtures guarantee functional integrity at the component level.

Read More

Gauges & Checking Fixtures