Win-Win Collaboration is the key

Kuasu Moldtec provides one-stop solutions for bespoke plastic moulding, covering CAD/CAE engineering, mold manufacturing, checking fixture building, and injection molding production. We also offer extended capabilities including mold components, inserts, mold bases, CNC milled parts, prototypes, and 3D printed parts. Get in touch to see how we can support your project.

Single-Point Contact

At Kuasu, we assign an experienced Senior Project Manager to oversee your project from start to finish. This single point of contact will coordinate all internal communications across our teams and guide you through every project phase:

3D part verification、Mold specifications & design review、Engineering change management、Sampling approval process、Provide weekly progress updates with:

Detailed reports and Real-time production photos

Your dedicated manager ensures seamless communication and complete transparency until final mold delivery.

Engineering Capabilities & Solutions

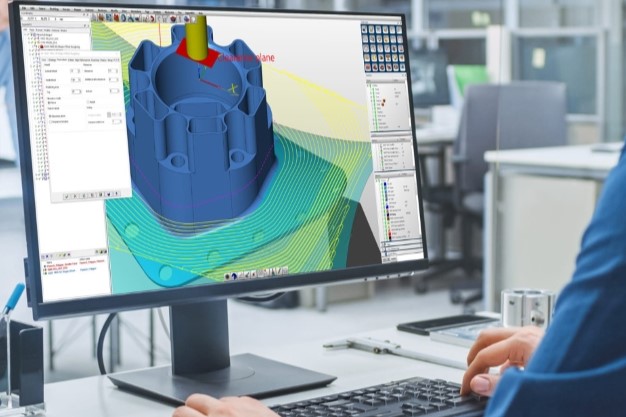

DFM / MoldFlow / CAD / Additive Manufacturing

Our team of 15 full-time senior engineers brings an average of 20+ years of hands-on experience in both mold design and manufacturing. This unique combination of design expertise and practical workshop knowledge enables us to develop innovative solutions for even the most complex technical challenges - all under one roof.

Our engineering team utilizes cutting-edge design software to conduct comprehensive part evaluations. We provide data-driven design optimizations tailored to your product's functional requirements and performance goals. Through rigorous upfront feasibility analysis, we deliver solutions that consistently exceed industry standards for manufacturability and quality.

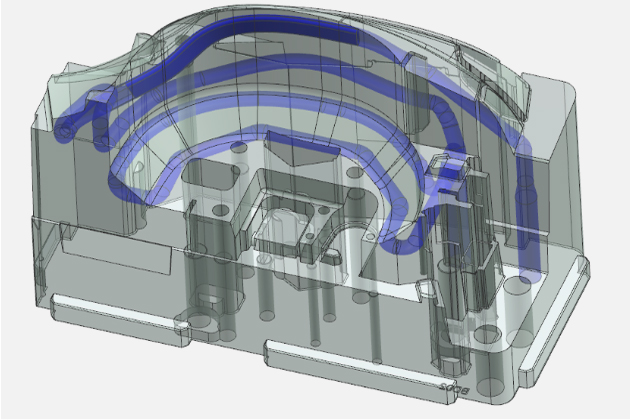

Moldflow simulation is fundamental to our design process. Our Silver-Certified analysts don't just evaluate standard parameters(gate placement, filling patterns, clamping force, air traps, and cycle time) - we go further by:

• Predicting part deformation through advanced simulation

• Implementing preemptive warpage compensation

• Optimizing designs before steel cutting begins

This proactive approach eliminates costly trial-and-error, ensuring right-first-time manufacturing.

When traditional solutions like BeCu or Ampco alloys can't resolve chronic hot spot issues, our engineers implement innovative additive manufacturing techniques to:

• Eliminate thermal bottlenecks

• Develop non-traditional cooling configurations

• Reduce cycle times by up to 30%

• Maintain dimensional stability

These advanced tooling solutions leverage the latest 3D printing technologies to achieve what conventional methods cannot.

Phase 1: Commercial & Initiation Stage

• Customer RFQ (Request for Quotation) & 3D Data Received

• Internal Technical Review & Risk Assessment

• Cost Calculation & Quotation Submission

• Purchase Order (PO) Receipt & Contract/Technical Agreement Sign-Off

• Project Team Formation & Official Kick-off Meeting

Phase 2: Design & Planning Stage

• DFM (Design for Manufacturability) Report Creation

• Customer Approval of DFM Report

• Detailed Mold Design & CAM Programming

• Internal Design Review

• Procurement of Materials (Steel, Standard Components)

• Incoming Quality Control (IQC)

Phase 3: Processing & Assembly Stage

• Machining (Milling, Turning, Grinding, CNC, EDM, etc.)

• In-Process Quality Control (IPQC)

• Mold Assembly (Fitting)

• Polishing & Texturing (ETCH/EDM)

• Final Quality Control (FQC) & Pre-Trial Inspection

• Complete dimensional check of the finished mold, core/cavity inserts, and movement functions.

• Mold Trial Preparation (Mounted on Press, Runner Prepared)

Phase 4: Trial & Validation Stage

• First Shot Trial (T1 Trial)

• Create Detailed T1 Trial Report

•Documents machine settings, process parameters, and includes pictures and measurements of sample parts.

• Customer Sample Evaluation & Report Feedback

• Mold Modification & Optimization

•This creates a (Closed Loop): Steps 18-21 repeat (T2, T3...) until samples meet all specifications.

• Customer Final Sample Approval (PPAP Approval)

Phase 5: Delivery & After-Sales Stage

• Final Inspection & Mold Pre-Acceptance at Factory

• Packaging & Shipping

• Mold Received by Customer & Final Acceptance (FAC)

• Project Closure: Data Archiving

• After-Sales Support & Preventive Maintenance Services

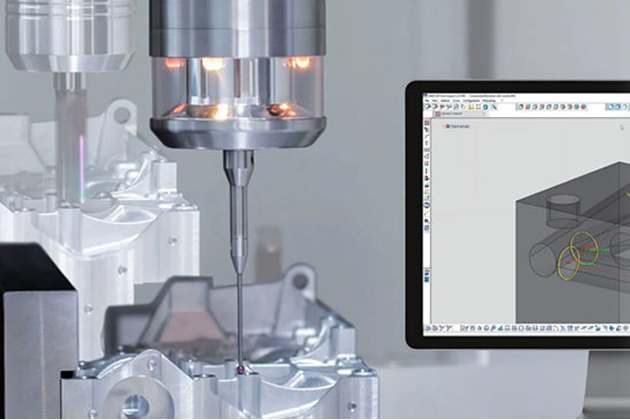

CNC Machining Technologies

Accuracy is the key

Our CNC machines achieve exceptional machining accuracy (±0.01mm) through:

• Advanced Thermal Compensation: State-of-the-art systems to eliminate thermal deformation

• High-Precision Feedback: Heidenhain™ linear encoders for real-time positioning accuracy

• Climate-Controlled Environment: Temperature-regulated machining areas

• In-Process Verification: Blum™ laser measurement systems

This combination of premium hardware and environmental controls ensures consistent, micron-level precision across all steel components.

Unlike traditional measurement methods, our CNC machines feature Renishaw optical probes that perform in-process measurements directly on the steel blocks. These probes automatically compare the machined surfaces to the 3D CAD geometry, allowing operators to verify accuracy before removing the inserts. This system not only ensures dimensional control but also significantly reduces CMM inspection workload. Similar to an automated vending system, our CNC operators have 24/7 access to pre-programmed cutting tools, with all tool usage automatically calculated into the machining costs for accurate cost tracking.

Milling Machines For Steel

Copper & Graphite Electrode Life-Cycle Management

Electric Discharge Machining (EDM)

Our manufacturing execution system (MES) enables comprehensive electrode parameter design during the CAM programming stage, including CMM measurement programs, tolerances, and EDM spark gap specifications. Each electrode receives a unique barcode identification for full traceability throughout the production process.

Our electrode production facility features advanced high-speed milling machines from industry-leading manufacturers including Germany's OPS-Ingersoll and Japan's Roku-Roku and Fanuc. These state-of-the-art machines handle both graphite and copper electrodes with exceptional precision.All equipment is integrated with Erowa automated holding systems, enabling:

• Micron-level machining accuracy

• Continuous 24/7 unmanned operation

• Consistent, high-quality electrode production

Every manufactured electrode undergoes CMM inspection, with the MES system automatically classifying it as approved or rejected. The system's true value lies in automatically transmitting measurement deviations to EDM machines for real-time spark gap compensation during the machining process. This technology delivers three key advantages:

• Achieves maximum machining accuracy

• Eliminates 100% of potential operator errors

• Reduces dependence on individual operator skill levels

EDM Machines

Tooling Capabilities

Mold Trial outs & Sampling, Functional Verification

We build all kind of the tools you are looking for

At Kuasu, we maintain full control over the entire mold production process - from design and machining to assembly, testing, and final verification. Our 300+ annual mold productions are entirely manufactured in our facility, with capabilities to handle: Mold sizes up to 20 tons Injection clamping forces up to 2000 tons All major mold classifications including SPI Class 101-104

At Kuasu, we employ a rigorous, multi-method approach to mold validation that eliminates potential defects through systematic testing. Our scientific trial methodology combines multiple verification techniques including:

Samples Delivery / Molds Transportation

Whatever for the delivery of samples, molded parts or the molds, we can always provide you a wide selection and solution in between the most economic, reliable and the fastest way.

Fast-Track Sampling:

Delivery Service.With Kuasu's China-based molds, you can receive sample parts at your doorstep within remarkable time frames - for instance, samples produced on Saturday can be delivered by Monday via DHL's global Priority service (guaranteed 72-hour delivery).

Cost-Effective Sea Freight Solution:

Sea freight remains the most economical option for mold transportation. For approximately $5,000 USD, we can ship a 20-foot container to most global ports within 4 weeks. Our strategic location just 60km from Yantian Port - China's largest container terminal - ensures efficient logistics handling and reduced inland transportation costs.

Our strategic location provides optimal logistics flexibility:

• Express Air: Ideal for urgent sample batches or mid-size molds (cost-effective with 2-5 day transit)

• Multi-Airport Access: Within 2-hour reach of major hubs (Shenzhen/Guangzhou/Hong Kong)

• 24/7 Shipment Monitoring: Real-time tracking from factory to destination

China-Europe Rail Alternative:

The China-Europe Railway Express has emerged as a reliable shipping alternative, offering:

• Direct access to 217 cities across 25+ European countries

• More consistent transit times compared to sea freight

• Enhanced cargo security and tracking capabilities

This rail network has become a vital link for international trade between Asia and Europe.